MIL-PRF-914C

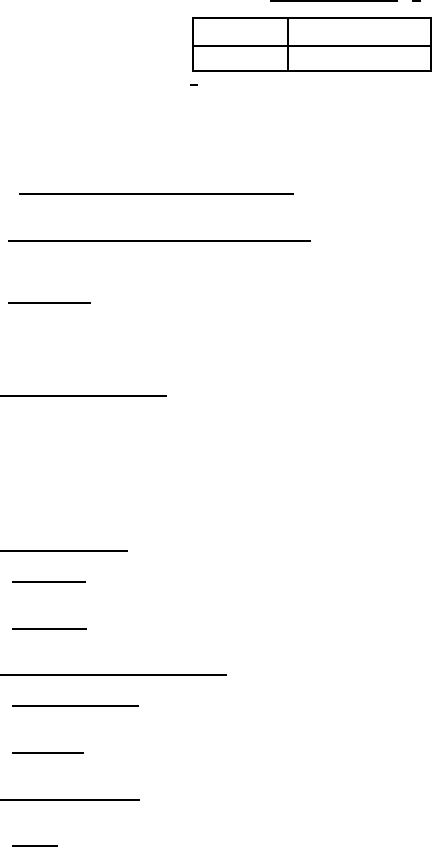

TABLE XI. Terminal Substitution. 1/

Termination

Allowable substitute

G

D

1/ Termination material "D" cannot be

substituted for a "G", but "D" can be

converted to a "G" in accordance

with A.5.3c by hot solder dipping and

performing 100% DC resistance

3.31.5 Substitution of ER type parts for non-ER parts. With procuring activity approval ER parts are a direct one-

way substitute for non-ER parts provided all other characteristics are equal or better.

3.32 Recycling, recovered, or environmentally materials. Recycled, recovered or environmentally preferable

materials should be used to the maximum extent possible provided that the material meets or exceeds the

operational and maintenance requirements, and promotes economically advantageous life cycle costs.

3.33 Workmanship. Networks shall be processed in such a manner as to be uniform in quality and shall meet the

requirements of 3.4 to 3.5.4 inclusive, and 3.5.6 and be free from other defects that will affect life, serviceability, or

appearance.

4. VERIFICATION

4.1 Classification of inspections. The inspections requirements specified herein are classified as follows:

a.

Qualification inspection (see 4.4).

b.

Verification of qualification (see 4.5).

c.

Conformance inspection (see 4.6).

Periodic group C inspection (see 4.7).

d.

4.2 Reliability and quality.

4.2.1 QPL system. The manufacturer shall establish and maintain a QPL system in accordance with 3.3.

Evidence of such compliance is a prerequisite for qualification and retention of qualification.

4.2.2 SPC system. A SPC program shall be established and maintained in accordance with EIA-557. Evidence of

such compliance is a prerequisite for qualification and verification of qualification.

4.3 Inspection conditions and precautions.

4.3.1 Inspection conditions. Unless otherwise specified herein, all inspections shall be performed in accordance

4.3.2 Precautions. Adequate precautions shall be taken during inspection to prevent condensation of moisture on

networks, except during moisture-resistance test and steady state humidity test.

4.4 Qualification inspection. Qualification inspection shall be performed at a laboratory acceptable to the

Government (see 6.3).

4.4.1 Sample. The sample shall be taken at random from a production run and shall be produced with equipment

and procedures normally used in production.

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business