MIL-PRF-19E

4.7.16 Vibration. high frequency (see 3.21). Resistors shall be tested in accordance with method 204 of

MIL-STD-202. The following details and exceptions shall apply:

a.

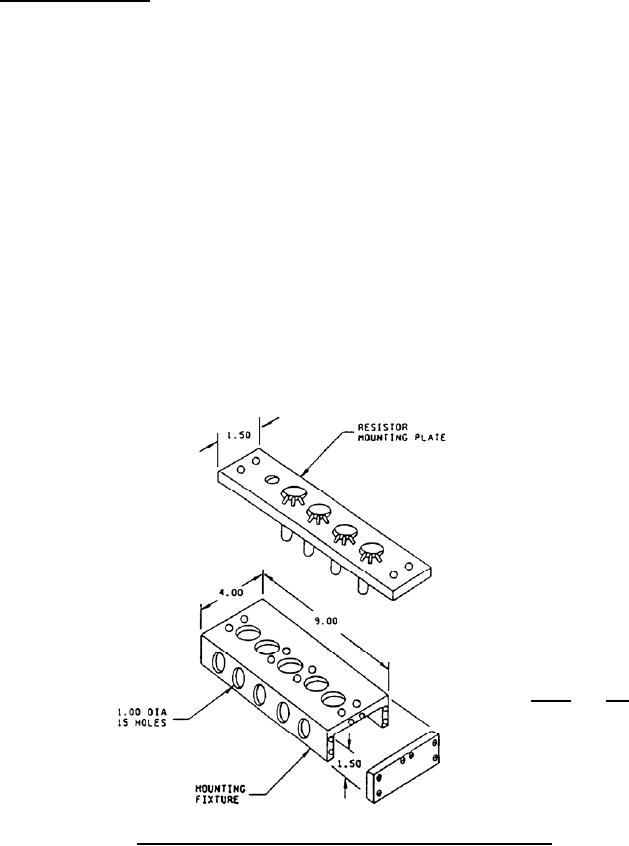

Mounting: By normal mounting means and affixed to an appropriate nonresonant mounting fixture. A

suggested mounting fixture is shown on figure 6. The mounting fixture shall be constructed in such a

manner as to insure that the points of the resistor mounting supports shall have the same motion as the

vibration test table. Test leads used during this test shall be as small as practicable (e.g., AWG size 22,

stranded) so that the influence of the test lead on the resistor shall be held to a minimum. The test lead

lengths shall be no longer than necessary. A shielded cable which may be necessary because of the field

surrounding the vibration test table, shall be clamped to the mounting fixture. In all cases, resistors shall be

mounted in relation to the test equipment in such a manner that the stress applied is in the direction which

would be considered the most detrimental. The contact arm shall be positioned at the approximate

midpoint of the resistor element.

Measurements after mounting: Total resistance shall be measured as specified in 4.7.3.1; resistance shall

b.

also be measured between the contact arm terminal and terminal number one.

c.

Test condition: C, part two.

d.

Motion: In each of two mutually perpendicular directions, one perpendicular and the other parallel to the

longitudinal axis of the resistor.

e.

Measurement during test: Each resistor shall be monitored to determine momentary discontinuity by a

method which shall at least be sensitive enough to monitor or register automatically any momentary

discontinuity of 0.1 millisecond or greater duration. A measurement of transient resistance change between

the contact arm terminal and terminal one shall also be made.

mm

Inches

1.00

25.40

1.50

38.10

4.00

101.60

9.00

228.60

FIGURE 6. Suggested mounting fixture and resistor mounting plate for shock test.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business