MIL-PRF-19E

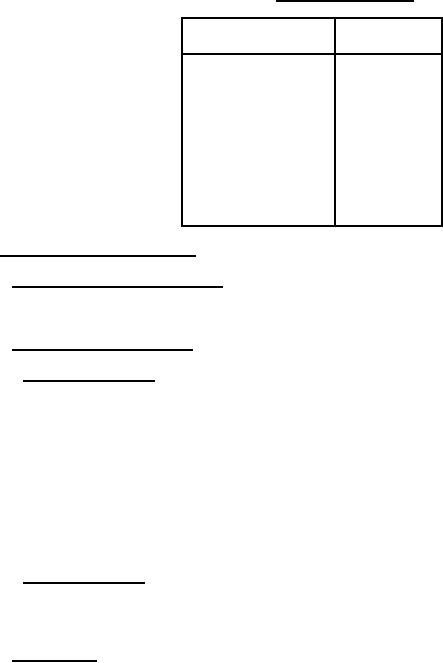

TABLE XII Group B sampling plan.

Subgroup 1

Lot size

sampling plan

1 to

25

3

26 to

50

5

51 to

90

6

91 to

150

7

151 to

280

10

281 to

500

11

501 to

1,200

15

1,201 to

3,200

18

3,201 to

10,000

22

10,001 and over

29

4.7 Methods of examination and test.

4.7.1 Visual and mechanical examination. Resistors shall be examined to verify that the materials, design.

construction, physical dimension, marking, and workmanship are in accordance with the applicable requirements

4.7.2 Dielectric withstanding voltage (see 3.7).

4.7.2.1 Atmospheric pressure. Resistors shall be tested in accordance with method 301 of MIL-STD-202. The

following details shall apply:

a.

Test potential: 900 volts root-mean-square (rms).

b.

Potential: From an alternating current (ac) supply at commercial line frequency and waveform.

c.

Points of application of test voltage: Between the terminals tied together and the external metal portions of

the resistors and metal mounting plate.

d.

Examination and measurements: During the tests, the leakage current shall be measured. At the

conclusion of the test, resistors shall be examined for evidence of mechanical damage.

4.7.2.2 Barometric pressure. Resistors shall be tested in accordance with method 105 of MIL-STD-202. A

potential of 450 volts rms (or as specified, see 3.1), from an alternating-current at commercial line frequency, and

waveform of not more than 100 hertz shall be applied for 1 minute between all terminals connected together and

bushing.

4.7.3 DC resistance (see 3.8). Resistors shall be tested in accordance with method 303 of MIL-STD-202. The

following details shall apply:

a.

Measuring apparatus: Different types of measuring test equipment (multimeter, bridges, or equivalent) are

permitted to be used on the initial and final readings of this test, provided the equipment is the same style,

model, or it can be shown that the performance of the equipment is equivalent. The supplier shall establish

and maintain a calibration system in accordance with NCSL Z540-1, ISO 10012-1, or equivalent system as

approved by the qualifying activity.

b.

Measurement energy for electronic test equipment: The measurement energy applied to the unit under test

shall not exceed 10 percent of the +25OC rated wattage times 1 second.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business