MIL-PRF-19E

4.7.11 Resistance to soldering heat (see 3.16). Resistors shall be tested in accordance with method 210 of

MIL-STD-202. The following details shall apply:

Measurement before test: DC resistance shall be measured as specified in 4.7.3.

a.

b.

Test condition letter: A.

c.

Depth of immersion in the molten solder: To a point 0.125 to 0.1875 inch (3.18 to 4.763 mm) from the

resistor body.

Examination and measurement after test: Four hours ±30 minutes after completion of test, the dc

d.

resistance shall be measured as specified in 4.7.3. Resistors shall be examined for evidence of

mechanical damage.

4.7.12 Rotational life (see 3.17).

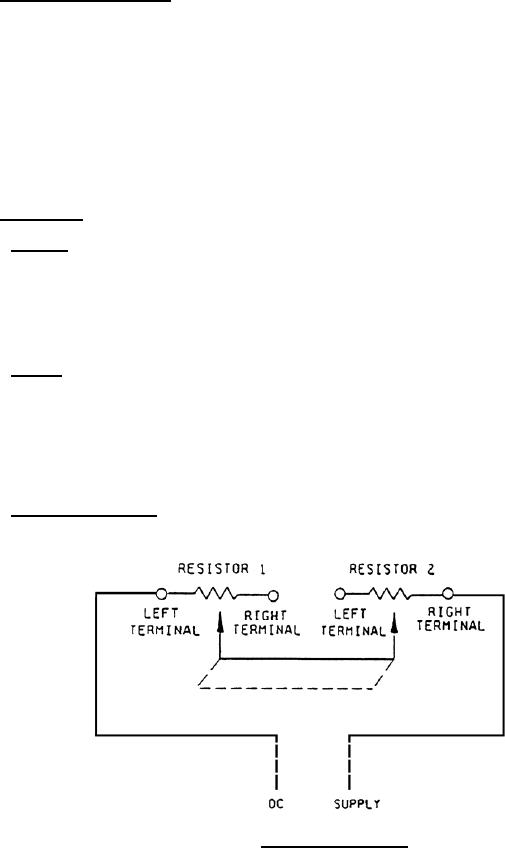

4.7.12.1 Mounting. During this test, resistors shall be centrally mounted on a 4 inch (102 mm) square, 0.050 inch

(1.27 mm) thick, steel panel, with their terminals positioned downward. Care should be taken to insure that side thrust

is minimized by the proper alignment of the resistors shafts with the drive shafts. The resistors shall be ganged in

pairs and each pair shall be connected in series as shown on figure 5 so that a nominally constant current flows

through the resistors irrespective of the contact arm position during oscillation of the shafts. The shafts shall be so

connected mechanically that they will turn simultaneously in the same direction. When performing this test on locking

bushing type resistors, the locking nut shall be removed.

4.7.12.2 Rotation. A dc potential equivalent to that required to dissipate rated wattage across the entire resistive

element of resistors having the same nominal total resistance as those under test, shall then be applied as shown on

figure 5. Resistor shafts shall then be continuously oscillated through not less than 98 percent of the total mechanical

rotation (see figure 1), at the rate of approximately 10 ±2 cycles per minute for not less than 4,000 cycles per day for a

total of 25,000 cycles. Locking bushing types shall be rotated for a total of 500 cycles. The contact arm shall oscillate

over the end of the element to which connection is made and proper contact of the contact arm with the winding shall

be maintained. Total resistance of resistors shall be ascertained at the end of every 5,000 cycles for all resistors

except the locking bushing type. The rotational life test shall be conducted at ambient room temperature.

4.7.12.3 Conformance inspection. At the option of the manufacturer, the sample units may be rotated at a rate of 8

to 30 cycles per minute.

FIGURE 5. Rotational life test circuit.

18

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business