MIL-PRF-49462C

4.6.2.1.3.3 Disposition of samples. The solderability test is considered a destructive test and samples

submitted to the solderability test shall not be supplied on the contract.

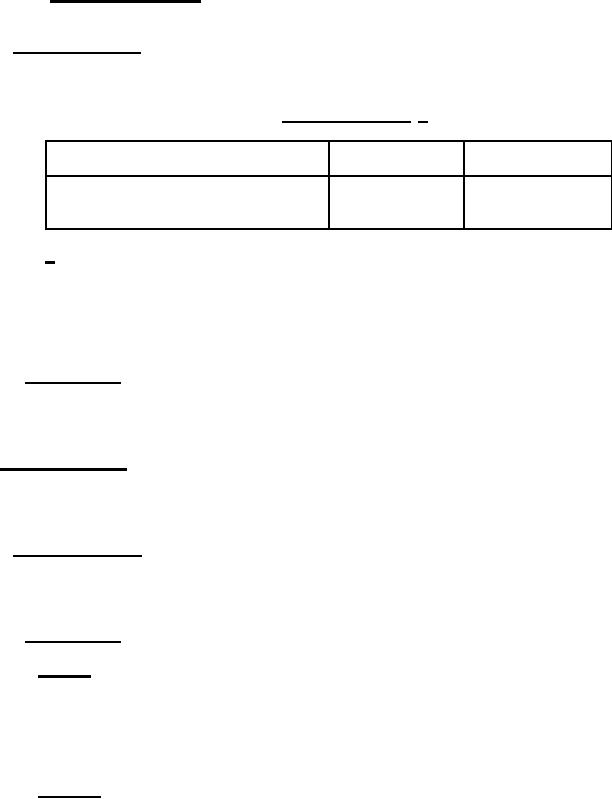

4.6.3 Group B inspection. Group B inspection shall consist of the inspections specified in table VIII in

the order shown. They shall be performed on sample units that have been subjected to and passed the

group A inspection.

TABLE VIII. Group B inspection 1/.

Inspection

Requirement

Method paragraph

paragraph

Resistance temperature characteristic

Dielectric withstanding voltage

Thermal shock

*

1/ If the manufacturer can demonstrate that this test has been performed for five

consecutive times with zero failures, the frequency of this tests, with the approval

of the qualifying activity, can be performed on an annual basis. If the design,

material, construction, or processing of the part is changed, or if there are quality

problems or failures, the qualifying activity may require resumption of the original

test frequency.

4.6.3.1 Sampling plan. Group B tests shall be performed on an inspection lot basis. A sample of 13

parts shall be randomly selected. If one or more defects are found, the lot shall be rescreened and

defects removed. A new sample of 13 parts shall be randomly selected. If one or more defects are found

in this second sample, the lot shall be rejected and shall not be supplied to this specification.

4.7 Periodic inspection. Periodic inspection shall consist of group C inspection. Except where the

results of these inspections show noncompliance with the applicable requirements (see 4.7.1.1.6),

delivery of products which have passed group A and group B inspections shall not be delayed pending

the results of these periodic inspections.

4.7.1 Group C inspection. Group C inspection shall consist of the tests specified in table IX in the

order shown. Group C inspection shall be performed on sample units of each style and selected from

inspection lots which have passed group A and group B inspections. Group C inspection samples shall

be representative of production.

4.7.1.1 Sampling plan.

4.7.1.1.1 Monthly. Every month, 10 sample units of each style, characteristic, and body enclosure of

any resistance value between the critical and lowest values shall be inspected. If none of these

resistance values produced during the month, resistors of the lowest resistance values produced shall be

inspected with one defective units allowed. If this sample fails, 10 additional sample units shall be

inspected with no defectives allowed, but no more than two defectives allowed for all 20 sample units

combined.

4.7.1.1.2 Quarterly. Every 3 month, 20 sample units of each style, characteristic, and body enclosure

of any resistance value between the critical and highest values shall be inspected. Ten sample units of

any resistance value between the critical and highest values shall be subjected to the inspection of

subgroup I, and 10 sample units of the value closest to the value above the critical value shall be

subjected to the inspection of subgroup 2. One defective unit will be allowed for each subgroup, but not

more than one defective for the two groups combined.

13

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business