MIL-PRF-49462C

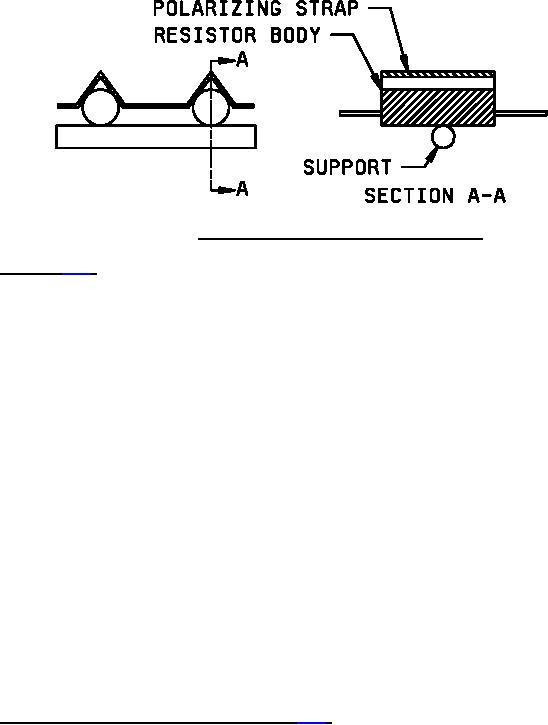

FIGURE 1. Mounting strap for moisture resistance test.

following details and exceptions shall apply:

a. Method of mounting: Resistors shall be mounted and soldered on lightweight terminals. The

effective length of each terminal shall be 1 inch. Resistors shall be arranged that the temperature

of any one resistor shall not influence the temperature of any other resistor. There shall be no

circulation of air over the resistors other than that caused by heat of the resistors.

b. Test temperature: +25°C ±5°C.

c. Initial measurement: DC resistance shall be measured at room temperature which shall be used

as the reference reading for all subsequent measurements under the same conditions

d. Operating conditions: Rated dc continuous working voltage shall be applied intermittently, 45

minutes "on" and 15 minutes "off", for 1,000 hours.

e. Test condition: D.

f. Measurement during test: DC resistance shall be measured at the end of the 15 minute "off"

periods, after, 250 hours +72 hours, -24 hours; 500 hours +72 hours, -24 hours; 1,000 hours +72

hours, -24 hours have elapsed. Measurement shall be made as near as possible to the specified

time but may be adjusted so that measurement need not be made during other than normal

workdays.

g. Examination after test: Resistors shall be examined for evidence of mechanical damage.

4.8.13 Resistance temperature characteristics (see 3.18). Resistors shall be tested in accordance with

method 304 of MIL-STD-202. The following details and exceptions shall apply:

a. Reference temperature: Room ambient temperature.

b. Test temperature: In accordance with table XI herein.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business