MIL-PRF-49462C

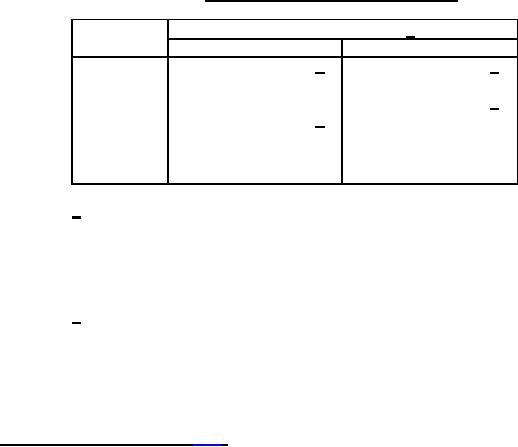

TABLE XI. Resistance temperature characteristic.

Temperature °C

Sequence

1/

Qualification inspection

Group B inspection

Room temperature 2/

Room temperature 2/

1

-15°C ±3°C

-55°C ±3°C

2

-55°C ±3°C

3

Room temperature 2/

+175°C ±3°C

4

Room temperature 2/

+65°C ±3°C

5

6

+125°C ±3°C

7

+175°C ±3°C

1/ At the option of the manufacturer the reverse sequence may be

as follows:

1

Room temperature

+175°C ±3°C

2

3

Room temperature

-55°C ±3°C

4

2/ This temperature shall be considered the reference temperature

for each of the succeeding temperatures.

c. Accuracy of temperature measurement: Resistors shall be maintained for 30 minutes to 45

minutes within 1°C at each of the test temperatures as specified in table XI herein. This tolerance

shall be maintained at the established test temperatures.

4.8.14 Shock (specified pulse) (see 3.19). Resistors shall be tested in accordance with method 213 of

MIL-STD-202. The following details and exceptions shall apply:

a. Special mounting means: Resistors shall be rigidly mounted on an appropriate jig fixtures with

their leads supported at a distance of 0.25 inch from the resistor body. The resistor shall be

mounted with body clamped or cemented to a flat surface. When used, the cement material shall

not extend above the center line in the horizontal plane or beyond the resistor body in the vertical

plane. In no case shall the resistor body be completely encapsulated. These fixtures shall be

constructed in a manner to insure that the points of the resistor mounting supports will have the

same motion as the shock table. Test leads used during this test shall be no larger than AWG size

22 stranded wire (not applicable for resistance value greater than 10 megohms). The test lead

strength shall be no greater than is necessary. In all cases, the resistors shall be mounted in such

a manner that the stress applied is in the direction which would be considered most detrimental.

b. Measurement before shock: DC resistance shall be measured as specified in 4.8.2.

c. Number and direction of applied shocks: The resistors shall be subjected to a total of 10 shocks in

each of two mutually perpendicular planes, 1 perpendicular and the other parallel to the

longitudinal axis of the resistor.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business