MIL-PRF-39005G

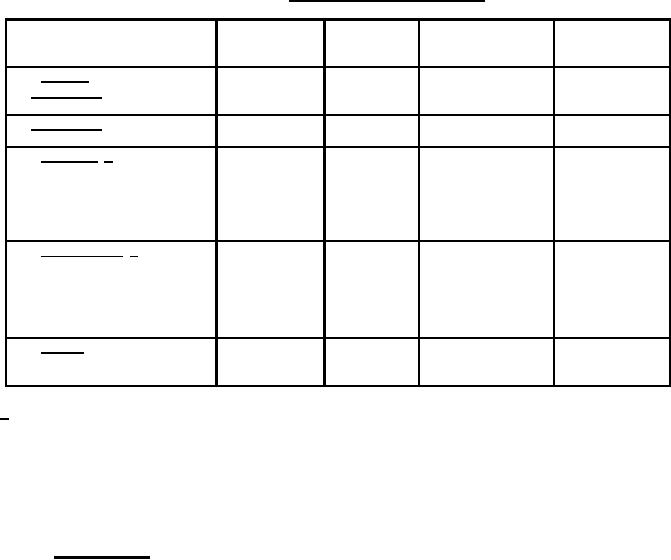

TABLE XIV. Group C inspection (ER only).

Inspection

Requirement

Test

Number of

Number of

paragraph

method

sample

failures

paragraph

Units for inspection

allowed

Monthly

Subgroup 1

Life

See 4.7.2

See 4.7.2

Subgroup 2

18 any value

1

Moisture resistance

Quarterly 1/

Dielectric withstanding voltage

Insulation resistance

Low temperature storage

18 highest value

1

Low temperature operation

Terminal strength

Semiannually 1/

Short time overload

Thermal shock

Resistance to soldering heat

6 any value

0

Shock, specified pulse

Vibration, high frequency

Annual

34 high

High temperature exposure

102 34 10 kohm

34 low

1

1/ If the manufacturer can demonstrate that these tests have been performed five consecutive times

with zero failures, these tests, with the approval of the qualifying activity, can be deleted. The

manufacturer, however, shall perform these tests every 3 years after the deletion as part of long

term design verification. If the design, material, construction, or processing of the part is changed,

or if there are any problems, the qualifying activity may require resumption of the specified testing.

Deletion of testing does not relieve the manufacturer from meeting the test requirements in case of

dispute.

4.7.1.1 Sampling plan. If more than 1,000 resistors of any style or style grouping are produced over

the maintenance period, the group C tests shall be performed as specified. If the production rate is less

than 1,000 resistors for any style or style grouping over the maintenance period, then the monthly,

quarterly, or semi-annual group C inspection may be postponed until at least 1,000 resistors of that style

or grouping are produced (except for the monthly life test). In any case, the monthly tests shall be

performed at least once every 3 months. The quarterly tests shall be performed at least every 6 months

and the semi-annual tests shall be performed at least once every year. This requirement is waived if the

manufacturer has obtained a reduced inspection status through the qualifying activity.

All qualified styles may be grouped together in a single sample. This can be accomplished by proportion

based on manufacturing percentages by style, equally divided by style, or by establishing an alternating

style sequence. In order to incorporate a style sampling grouping, a written description must be

presented and approved by the qualifying activity. This plan must assure that the grouping only combines

styles of the same basic design, encapsulation material, and the same element type.

20

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business