MIL-PRF-22097J

4.6.2.1.3 Subgroup 3 (solderability). A sample of five parts from each inspection lot shall be selected and

subjected to the subgroup 3 solderability test. If one or more defects, the lot shall be considered to have failed. As

an option, the manufacturer may use electrical rejects from the subgroup 1 tests for all or part of the sample. If there

are one or more defects, the lot is rejected. The manufacturer may use one of the following options for corrective

action:

a.

Each production lot that was used to form the failed inspection lot shall be individually submitted to the

solderability test. Production lots that pass the solderability test are available for shipment. Production lots

failing the solderability test can be submitted to the solder dip procedure in 4.6.2.1.3b.

b.

The lot is submitted to a 100 percent solder dip using an approved solder dip process in accordance with the

appendix. A subsequent solderability test shall then be performed. If the lot passes, it is available for

shipment; if the lot fails, the manufacturer may perform the hot solder dip one additional time. If the lot fails

to pass, the lot is considered rejected and shall not be supplied to this specification.

4.6.2.1.4 Disposition of samples. The solderability test is considered a destructive test and samples submitted to

the solderability test shall not be supplied to this specification.

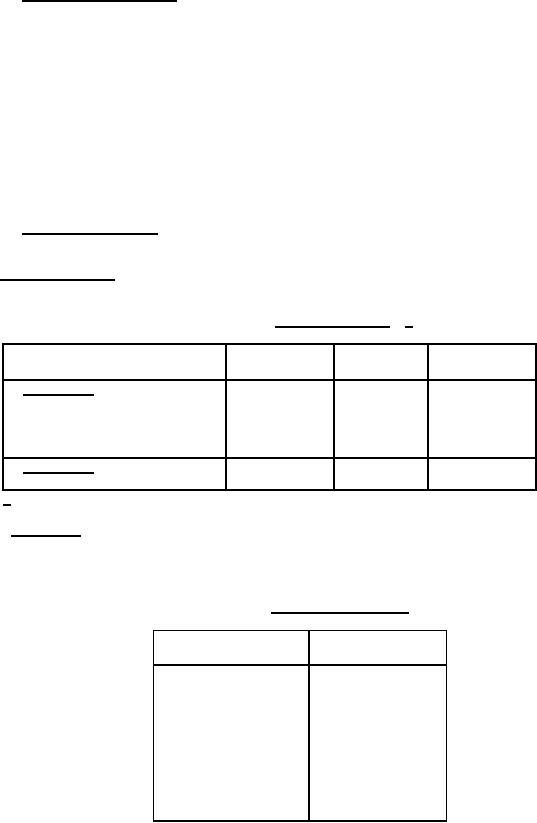

4.6.3 Group B inspection. Group B inspection shall consist of the tests specified in table VIII, in the order shown,

and the sample shall be selected from inspection lots that have passed group A inspection.

TABLE VIII. Group B inspection. 1/

Requirement

Method

Sampling

Inspection

paragraph

paragraph

Procedure

Subgroup 1

Actual effective electrical travel

Dielectric withstanding voltage

Insulation resistance

Torque

Subgroup 2

Thermal shock

1/ See table XII.

4.6.3.1 Subgroup 1. A sample of parts shall be randomly selected in accordance with table IX. If one or more

defects are found, the lot shall be reworked or screened and defectives removed. After reworking or screening and

removal of defectives, a new sample of parts shall be randomly selected in accordance with table IX. If one or more

defects are found in the second sample, the lot shall be not supplied to this specification.

TABLE IX. Group B sampling plan.

Subgroup 1 and 2

Lot size

sampling plan

1

to

25

3

26

to

50

5

51

to

90

6

91

to

150

7

151

to

280

10

281

to

500

11

501

to

1,200

15

1,201

to

3,200

18

3,201

to 10,000

22

10,000

and over

29

15

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business