MIL-PRF-39015E

4.6.3.2.1 Subgroup 1 tests. Subgroup 1 tests shall be performed on a production lot basis on 100 percent

of the product supplied under this specification. Resistors that are out of resistance tolerance, or which

experience a change in resistance greater than that permitted for the tests of this subgroup, shall be removed

from the lot. Only lots having not more than 10 percent rejects, or one resistor, whichever is greater, due to

exceeding the specified resistance change limit, as a result of subgroup 1 tests, shall be furnished on orders.

Corrective action shall be taken on such values and new pieces furnished.

4.6.3.2.2 Manufacturer's production inspection. If the manufacturer performs tests equal to or more

stringent than those specified in group A, subgroup 1, as the final step of this production process, group

A, subgroup 1 inspection may be waived and the data resulting from the manufacturer's production tests

may be used instead. Authority to waive the subgroup 1 inspection shall be granted by the qualifying

activity only. The following criteria must be complied with:

a. Production tests are identical to or more stringent than those specified for subgroup 1 tests.

b. One hundred percent of the product supplied to these tests.

c.

Failure criteria are identical to, or more stringent than, those specified for subgroup 1 tests.

d. Lot rejection criteria are identical to, or more stringent than, those specified for subgroup 1 tests.

e. Once approved, future changes require approval from the qualifying activity.

4.6.3.2.3 Subgroup 2 tests. The subgroup 2 tests shall be performed on an inspection lot basis for ER

parts. A random sample of resistors shall be selected in accordance with table VII. In the event of one or

more failures, the lot is rejected. The rejected lot may be rescreened and the defects removed and

resubmitted to the table VII sample plan. If one or more defects are found in this second sample, the lot

is rejected and shall not be supplied to this specification. (NOTE: This corrective action applies to the

original quality defect found. If another defect type is found in the second sample, a rescreen for that

defect is also permitted).

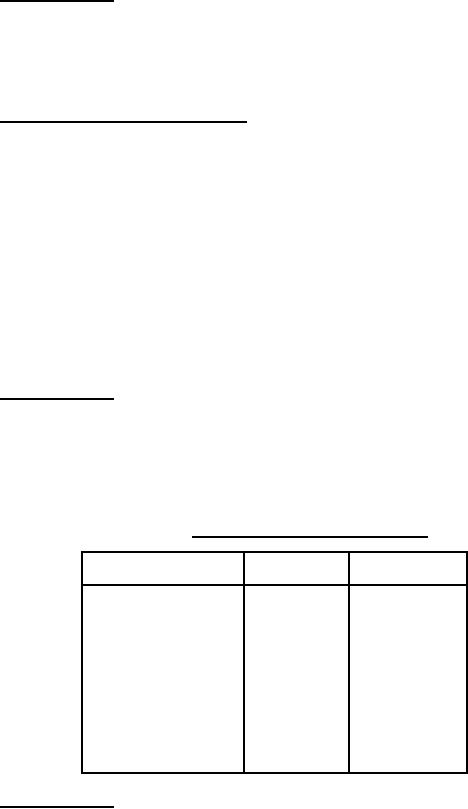

TABLE VII. Sampling plans for PPM categories.

Lot size

Sample size

Sample size

PPM

subgroup 2

100 percent

100 percent

1-

13

13

100 percent

14 -

125

13

125

126 -

150

20

125

151 -

280

29

125

281 -

500

34

125

501 - 1,200

42

125

1,201 - 3,200

50

125

3,201 - 10,000

60

294

10,001 - 35,000

74

294

35,001 - 150,000

90

345

150,001 - 500,000

102

435

500,001 and over

4.6.3.2.4 Subgroup 3 tests. Subgroup 3 shall be performed on an inspection lot basis. A sample of 13

parts shall be randomly selected. If one or more defects are found, the lot shall be rescreened and

defects removed. A new sample of 13 parts shall be randomly selected. Of one or more defects are

found in this second sample, the lot shall be rejected and shall not be supplied to this specification.

17

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business