MIL-PRF-39005G

4.6.3.2.4 Subgroup 3.

4.6.3.2.4.1 Sampling plan. Thirteen samples shall be selected randomly from each inspection lot and

subjected to the subgroup 3 solderability test. The manufacturer may use electrical rejects from subgroup

1 screening tests for all or part of the samples to be used for solderability testing. If there are one or more

defects, the lot shall be considered to have failed.

4.6.3.2.4.2 Rejected lots. In the event of one or more defects, the inspection lot is rejected. The

manufacturer may use one of the following options to rework the lot.

a. Each production lot that was used to form the failed inspection lot shall be individually submitted to

the solderability test as required in 4.8.6. Production lots that pass the solderability test are

available for shipment. Production lots failing the solderability test can be reworked only if

submitted to the solder dip procedure in 4.6.3.2.4.2b.

b. The manufacturer submits the failed lot to a 100 percent solder dip using an approved solder dip

measurements required in group A, subgroup 1 tests shall be repeated on 100 percent of the lot.

The PDA for the electrical measurements shall be as for the subgroup 1 tests. Additional samples

shall be selected in accordance with table XII and subjected to the solderability test with zero

defects allowed. If the lot fails this solderability test, the lot may be reworked a second time and

retested. If the lot fails the second rework, the lot shall be considered rejected and shall not be

furnished against the requirements of this specification.

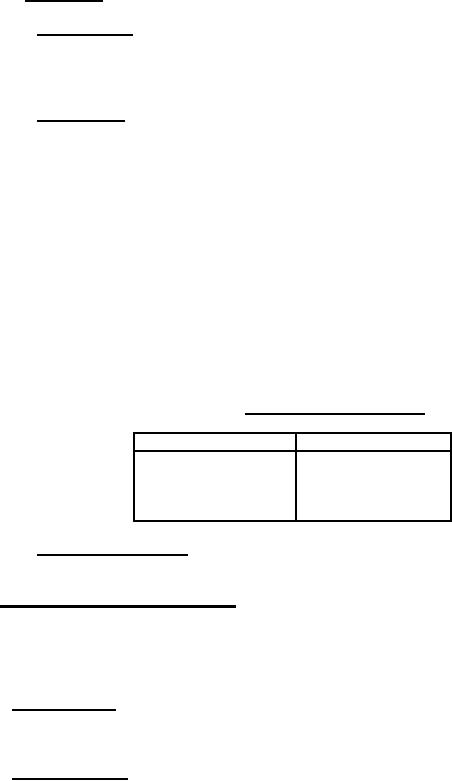

TABLE XII. Solderability sampling plan.

Lot size

Sample size

1 to 3,200

5

3,201 to 10,000

8

10,001 to 35,000

13

35,001 and over

20

4.6.3.2.4.3 Disposition of samples. The solderability test is considered a destructive test and samples

submitted to the solderability test shall not be supplied on the contract.

4.6.4 PPM assessment (non-ER and ER). The manufacturer shall establish and maintain a system for

assessing the average outgoing quality in PPM of lots supplied to this specification. This PPM

assessment should be based on inspections performed on each inspection lot to verify that resistors meet

dc resistance and tolerance requirements. For ER resistors, this inspection shall occur after the group A,

subgroup 1, 100 percent screens have been completed.

4.6.4.1 Sampling plans. Minimum sample sizes for inspection lots shall be selected in accordance with

table XI. For non-ER resistors, the sampling system and plan used for the group A inspection (see

4.6.3.1) may be the basis for assessing PPM.

4.6.4.2 PPM calculations. PPM calculations shall be based on the accumulated results of the initial

sample. Calculations and exclusions shall be in accordance with EIA-554-1.

18

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business