MIL-PRF-39002C

4.6.11.1 Setting stability. The contact arm shall be set at approximately 40 percent of the actual effective-electrical

travel. An adequate dc test potential shall be applied between the end terminals. The voltage between the end

terminals, and the voltage between one end terminal and the contact arm, shall be measured and applied to the

following formula:

E1 x 100

Setting stability in percent of total applied voltage =

E2

The difference between the initial measurement made before environmental test and the measurement made after

the test indicated the percent change.

4.6.12 Resistance-temperature characteristic (see 3.17). Resistors shall be tested in accordance with method 304

of MIL-STD-202. The following details shall apply.

a.

Test temperatures: As specified in table VII.

b.

Measurements at end of each period: Total resistance shall be measured as specified in 4.6.2.1, at the

temperature maintained during the period.

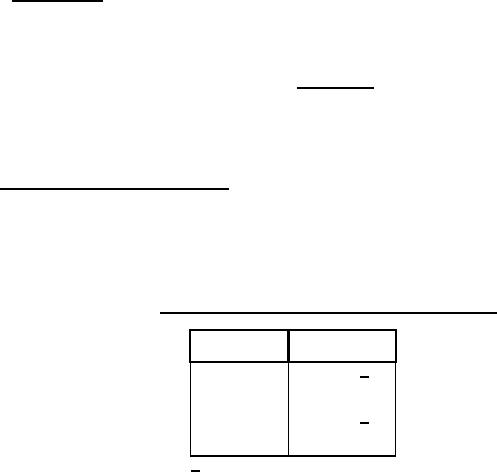

TABLE VII. Resistance-temperature characteristic test temperatures.

Temperature

Sequence

O

in C

1

25 1/

2

-15

3

-55

4

25 1/

5

65

6

135

1/

This temperature shall be

considered the reference

temperature for each of the

succeeding temperatures.

NOTE: At the option of the manufacturer, the reverse sequence of table VII may be as follows:

1 - Room temperature.

2 - Series of hot temperatures.

3 - Room temperature.

4 - Series of cold temperatures.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business