MIL-PRF-27208F

APPENDIX A

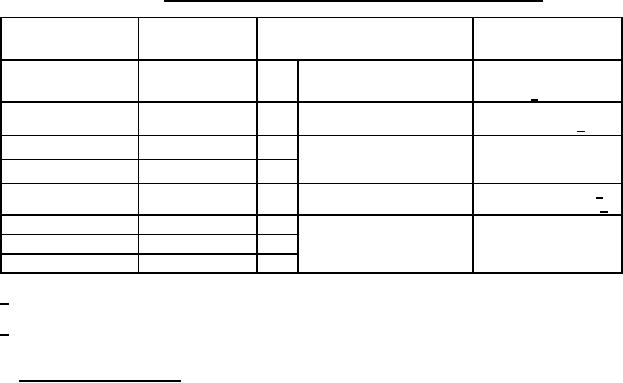

TABLE A-I. Additional testing required to extend qualification to other styles.

Tests from Table IV to

Terminal type for

Terminal types

be preformed on

which qualification

Number of additional sample units

qualified

additional sample units

is sought

Test group I, moisture

3 highest resistance values

P, W, or X

L

6

resistance and terminal

3 lowest resistance values

strength 1/

3 highest resistance values

Test group I and III and

P

W or X

6

terminal strength 1/

3 lowest resistance values

P

Y

6

Visual and mechanical

Any resistance value

examination

W or X

P

6

6 highest resistance values

Test groups I, III, VII 2/,

L

P, W, or X

9

3 lowest resistance values

and terminal strength 1/

W or X

P

6

Visual and mechanical

Any resistance value

X

W

6

examination

W

X

6

1/ Where terminal strength is required, the six sample units from the previous test, or six additional

sample units may be used at the option of the supplier.

2/ All nine sample units shall be submitted to test group I, then subdivided with six sample units

submitted to test group III and the remaining three sample units submitted to test group VII.

A.5.2 Qualifying activity approval. Approval of the solder dip process will be based on one of the following options:

a. When the original lead finish qualified was hot solder dip lead finish 52 of MIL-STD-1276 (Note: The 200

microinch maximum thickness is not applicable). The manufacturer shall use the same solder dip process for

retinning as is used in the original manufacture of the product.

b. When the lead originally qualified was not hot solder dip lead finish 52 of MIL-STD-1276 as prescribed in

A.5.2a, approval for the process to be used for solder dip shall be based on the following test procedure:

(1) Thirty samples of any resistance value for each style and lead finish are subjected to the manufacturers'

solder dip process. Following the solder dip process, the resistors are subjected to the resistance test

(and other group A electricals). No defects are allowed.

(2) Ten of the 30 samples are then subjected to the solderability test. No defects are allowed.

(3) The remaining 20 samples are subjected to the resistance to solder heat test followed by the moisture

resistance test. No defects are allowed.

29

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business