MIL-PRF-27208F

4.7 Methods of examination and test.

4.7.1 Visual and mechanical examination. Resistors shall be examined to verify that the materials, design,

construction, physical dimensions, marking, and workmanship are in accordance with the applicable requirements

(see 3.1, 3.3 to 3.3.2 inclusive, 3.4 to 3.4.3, 3.4.4 to 3.4.7 inclusive, 3.29 to 3.32, inclusive and 3.34).

4.7.2 Resistance (see 3.7). Resistors shall be tested in accordance with method 303 of MIL-STD-202. Measuring

instruments used for initial and final readings of this test, can be of different styles or models provided performance is

equivalent or better.

a. Measuring apparatus: The same measuring instrument shall be used for all resistance measurements in any

one test, but not necessarily for all the tests.

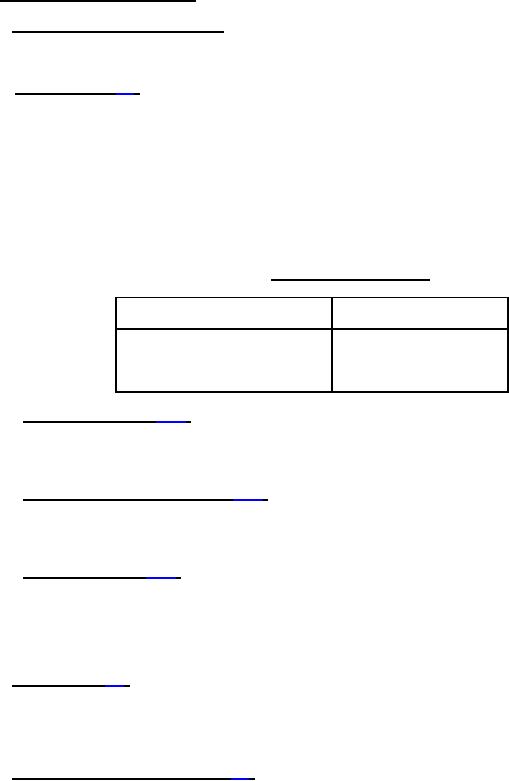

b. Test voltage: Measurements of resistance shall be made by using the test voltage specified in table X. The

test voltage chosen, whether it be maximum or a lower voltage which would still provide the sensitivity

required, shall be applied across the terminals of the resistor. This same voltage shall be used whenever a

subsequent measurement is made.

TABLE X. DC resistance test voltage.

Total resistance

Maximum test voltage

nominal (in ohms)

(in volts)

10 to 100 incl.

1.0

Over 100 to 1,000 incl

3.0

Over 1,000 to 10,000 incl

10.0

Over 10, 000 to 0.1 megohm, incl

30.0

4.7.2.1 Total resistance (see 3.7.1). The total resistance shall be measured as specified in 4.7.2, between the

resistance element end terminals (terminals 1 and 3 of figure 1) with contact arm against a stop. The positioning of

the contact arm and terminal shall be the same for all subsequent measurements of the total resistance on the same

specimen.

4.7.2.2 Absolute minimum resistance (see 3.7.2). The contact arm shall be positioned at one end of the resistance

element, so that a minimum value of resistance shall be measured as specified in 4.7.2 between the contact arm and

the corresponding end terminal. The same procedure shall be followed for the other end of the resistance element.

Rated current through the resistance element shall not be exceeded during this measurement.

4.7.2.3 End resistance (see 3.7.3). The contact arm shall be positioned at the extreme counterclockwise limit of

mechanical travel, and the resistance shall be measured as specified in 4.7.2 between the contact arm and the

corresponding end terminal. The contact arm shall then be so positioned at the extreme clockwise limit of

mechanical travel, and the resistance shall be measured as specified in 4.7.2 between the contact arm and

corresponding end terminal. Clockwise and counterclockwise signifies the direction of rotation of the operating shaft

when the resistor is viewed from the shaft end.

4.7.3 Continuity (see 3.8). The operating shaft actuator shall be rotated at a uniform rate such that the wiper

traverses the effective electrical travel in both direction within 1.0 ±0.250 minutes. During this rotation, a electrical

device shall be connected between the wiper and either end terminal and monitored for smooth and unidirectional

change in voltage or resistance. Precaution shall be exercised to prevent excessive current flow in the resistor during

the test.

4.7.4 Actual effective electrical travel (see 3.9). The actual effective electrical travel shall be measured by placing

the resistor in a device and circuit which will indicate both angular position of the operating shaft and voltage output.

The actual effective electrical travel will be the number of turns or degrees of the operating shaft in which a change in

contact arm position gives a measurable change in voltage output.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business