MIL-PRF-22684F

APPENDIX A

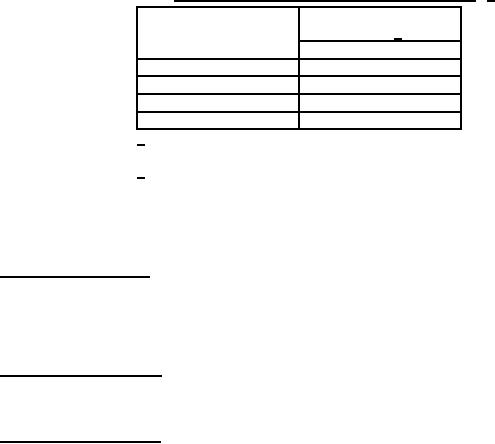

TABLE A-I. Critical resistance value for qualification inspection. 1/

Critical resistance

Style

value 2/

Megohms

RL07

0.240

RL20

0.240

RL32

0.240

RL42

0.120

1/ Maximum continuous working voltage shall be

applied (see 3.1).

2/ The critical resistance value is the maximum standard

resistance value which will dissipate full wattage

when the maximum continuous working voltage is applied.

A.4 EXTENT OF QUALIFICATION

A.4.1 Extension of qualification. The resistance ranges include in the qualification of any one style and terminal

shall be between any two adjacent-resistance values which pass the required qualification inspection. Qualification

of G resistance-tolerance resistors will also qualify J resistance-tolerance resistors.

A.5 SOLDER DIP (RETINNING) LEADS

A.5.1 Solder dip (retinning) leads. The manufacturer (or their authorized category B or category C distributor) may

solder dip/retin the leads of product supplied to this specification provided the solder dip process (see A.5.2 of this

appendix) or an equivalent process has been approved by the qualifying activity.

A.5.2 Qualifying activity approval. Approval of the solder dip process will be based on one of the following options:

a.

When the original lead finish qualified was hot solder dip lead finish 52 of MIL-STD-1276 (NOTE: The 200

microinch maximum thickness is not applicable). The manufacturer shall use the same solder dip process

for retinning as is used in the original manufacture of the product.

When the lead originally qualified was not hot solder dip lead finish 52 of MIL-STD-1276 as prescribed in

b.

A.5.2a, approval for the process to be used for solder dip shall be based on the following test procedure:

(1) Thirty samples of any resistance value for each style and lead finish are subjected to the manufacturers

solder dip process. Following the solder dip process, the resistors are subjected to the dc resistance test

and other group A electricals. No defects are allowed.

(2) Ten of the 30 samples are then subjected to the solderability test. No defects are allowed.

(3) The remaining 20 samples are subjected to the resistance to solder heat test followed by the moisture

resistance test. No defects are allowed.

(NOTE: Solder dip of gold plated leads is not allowed.)

22

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business