MIL-PRF-83530C

6.3 Qualification. With respect to products requiring qualification, awards will be made only for products which are,

at the time of award of contract, qualified for inclusion in the Qualified Products List whether or not such products

have actually been so listed by that date. The attention of the contractors is called to these requirements, and

manufacturers are urged to arrange to have the products that they propose to offer to the Federal Government tested

for qualification in order that they may be eligible to be awarded contracts or orders for the products covered by this

specification. Information pertaining to qualification of products may be obtained from Defense Supply Center,

Columbus, ATTN: DSCC-VQP, P.O. Box 3990, Columbus, Ohio 43218-3990

6.4 Tin whisker growth. The use of alloys with tin content greater than 97 percent, by mass, may exhibit tin

whisker growth problems after manufacture. Tin whiskers may occur anytime from a day to years after manufacture

and can develop under typical operating conditions, on products that use such materials. Conformal coatings applied

over top of a whisker-prone surface will not prevent the formation of tin whiskers. Alloys of 3 percent lead, by mass,

have shown to inhibit the growth of tin whiskers. For additional information on this matter, refer to

ASTM-B545 (Standard Specification for Electrodeposited Coatings of Tin).

6.5 Application notes.

6.5.1 Caution note. Should the varistor be subjected to surge currents and energy levels in excess of maximum

ratings, it may physically fail by package rupture or expulsion of material. It is recommended that protective fusing be

used. If not fused, the resistor should be located away from other components or be physically shielded from them.

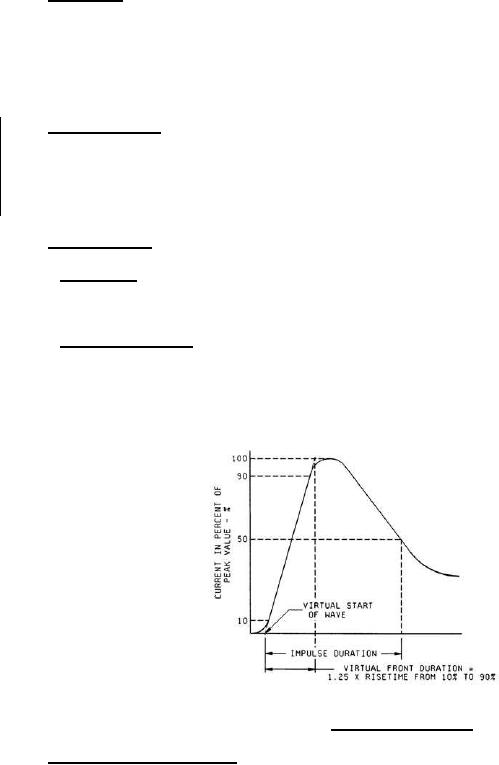

6.5.2 Current test waveform. All tests requiring an impulse of current uses the waveform of figure 1. The

waveform is specified by its peak current value and by its time dimensions; for example, 8 x 20 μS, where 8 is the

virtual front duration and 20 is the impulse duration in μS. The applied test waves are accurate to a tolerance of

±10% for virtual front duration, and to a tolerance of ±20% for impulse duration.

FIGURE 1. Pulse current waveform.

6.6 Subject term (key word) listing.

Suppressing transients

Varistor

Nominal voltage

Voltage tolerance

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business