MIL-PRF-39035E

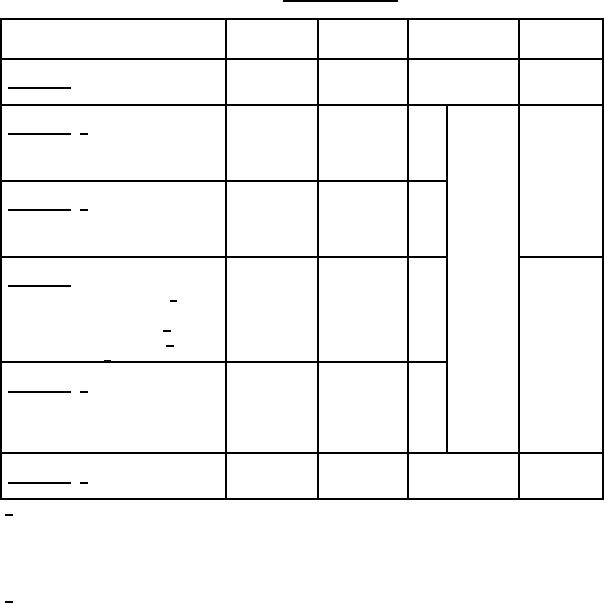

TABLE X. Group B inspection.

Requirement

Test method

Number of

Number of

Inspection

paragraph

paragraph

samples

defectives

Quarterly

Subgroup 1

Life

See 4.7.2.1

See 4.7.2.1

Quarterly

Subgroup 2 1/

Resistance temperature characteristic

12

Moisture resistance

Contact resistance variation

1

Quarterly

Subgroup 3 2/

12

Rotational life

Contact resistance variation

Terminal strength

Semiannually

6 highest

Subgroup 1

6 lowest

Resistance to soldering heat 1/

12

Immersion

High temperature exposure 2/

Contact resistance variation 2/

Integrity of shaft 1/

Semiannually

Subgroup 2 2/

Setability

1

12

Low temperature operation

Shock (specified pulse)

Vibration, high frequency

Semiannually

Subgroup 3 1/

Resistance to solvents

3 any value

0

1/

If the manufacturer can demonstrate that this test has been performed for five consecutive

times with zero failures, the frequency of this test, with approval of the qualifying activity, can

be performed on an annual basis. If the design, material, construction, or processing of the part

is changed, or if there are any quality problems or failures, the qualifying activity may require

resumption of the original test frequency.

2/

If the manufacturer can demonstrate that this test has been performed for five consecutive

times with zero failures, these tests, with approval of the qualifying activity, can be deleted.

The manufacturer however, shall perform these tests every three years after the deletion as

part of long term design verification. If the design, material, construction, or processing of the

part is changed, or if there are any problems, the qualifying activity may require resumption of

the specified testing. Deletion of testing does not relieve the manufacturer from meeting the

test requirement in case of dispute.

19

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business