MIL-PRF-39035E

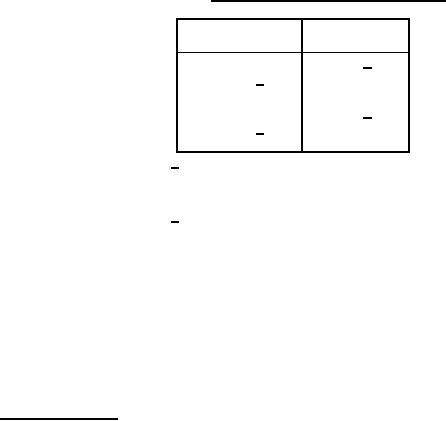

TABLE XII. Resistance-temperature characteristics.

Temperature

Sequence

in OC (± 3OC)

1

25 1/

2 2/

-15

3

-55

4

25 1/

5 2/

62

6

150

1/

This temperature shall be considered

the reference temperature for each of

the succeeding temperatures.

2/

Not applicable in conformance

inspection.

Note: At the option of the manufacturer, the reverse sequence may be as follows:

± 3OC

1.

25

± 3OC

2.

65

± 3OC

3.

150

± 3OC

4.

25

± 3OC

5.

-25

± 3OC

6.

-55

4.8.15 Moisture resistance (see 3.20). The resistors shall be tested in accordance with method 106 of

MIL-STD-202. The following details and exceptions shall apply:

a.

Mounting: Resistors shall be clamped or otherwise mounted with terminals exposed on a stainless-steel

panel of sufficient size to extend beyond the resistor extremities, and in such a manner as to allow

electrical connections to be made to the terminals.

b.

Initial measurement: Immediately following the initial drying period, total resistance shall be measured as

specified in 4.8.5.1.

c.

Polarization and loading voltage: The resistors shall be divided into two equal groups; one group shall be

subjected to polarization and the other group to load.

(1) Polarization: During steps 1 to 6 inclusive, a 100 volt dc potential shall be applied with the positive

lead connected to the resistor terminals tied together, and the negative lead connected to the

mounting plate.

(2) Loading voltage: During the first 2 hours of steps 1 and 4, a dc test potential equivalent to 100

percent rated wattage shall be applied to the resistors.

d.

Test procedure: The moisture resistance cycling requirements shall be as follows: For qualification

inspection - 20 cycles; For group B inspection - 10 cycles. Every 6 months, the group B quarterly test

shall be - 20 cycles.

26

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business