MIL-PRF-39035E

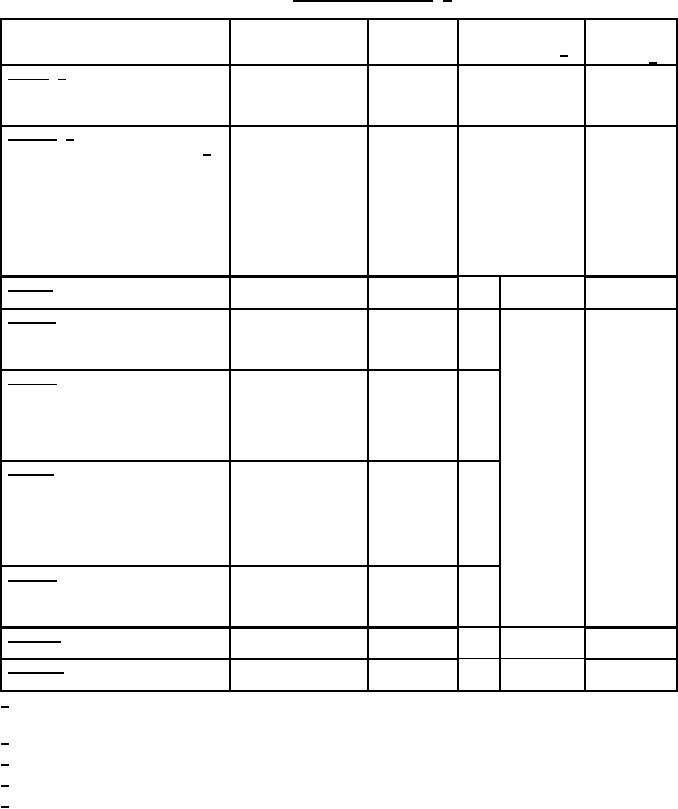

TABLE VI. Qualification inspection. 1/

Number of

Requirement

Test method

Number of sample

defectives

Inspection

paragraph

paragraph

to be inspected 2/

allowed 3/

Group I 4/

Conditioning

All sample units

N/A

Contact resistance variation

Immersion

Group IA 4/

Visual and mechanical examination 5/

All sample units

Actual effective electrical travel

except for

N/A

End resistance

Group II

Dielectric withstanding voltage

Insulation resistance

Torque

Thermal shock

Group II

0

Solderability

6

any value

Group III

Resistance temperature characteristic

12

Moisture resistance

Contact resistance variation

Group IV

Setability

Shock (specified pulse)

12

Vibration, high frequency

Contact resistance variation

Salt spray (corrosion)

6 highest

1

Group V

6 lowest

Resistance to soldering heat

Low temperature operation

12

Low temperature storage

High temperature exposure

Contact resistance variation

Integrity of shaft

Group VI

Rotational life

12

Contact resistance variation

Terminal strength

51 highest

Group VII

102

51 lowest

1

Life

Group VIII

0

Resistance to solvents

3

any value

1/

Group I tests need not be performed if manufacturer presents certified data proving that tests have been

previously performed on the qualification sample units.

2/

See appendix for details.

3/

Failure of one resistor in one or more tests of a group shall be charged as single defective.

4/

Nondestructive tests.

5/

Marking shall be considered defective only if illegible or missing.

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business