MIL-PRF-39002C

6.10 Tin whisker growth. The use of alloys with tin content greater than 97 percent, by mass, may exhibit tin

whisker growth problems after manufacture. Tin whiskers may occur anytime from a day to years after manufacture

and can develop under typical operating conditions, on products that use such materials. Conformal coatings applied

over top of a whisker-prone surface will not prevent the formation of tin whiskers. Alloys of 3 percent lead, by mass,

have shown to inhibit the growth of tin whiskers. For additional information on this matter, refer to ASTM-B545

(Standard Specification for Electrodeposited Coatings of Tin).

6.11 Environmentally preferable material. Environmentally preferable materials should be used to the maximum

extent possible to meet the requirements of this specification. As of the dating of this document, the U.S.

Environmental Protection Agency (EPA) is focusing efforts on reducing 31 priority chemicals. The list of chemicals

and additional information is available on their website https://www.epa.gov/osw/hazard/wastemin/priority.htm. Use of

these materials should be minimized or eliminated unless needed to meet the requirements specified herein (see

Section 3).

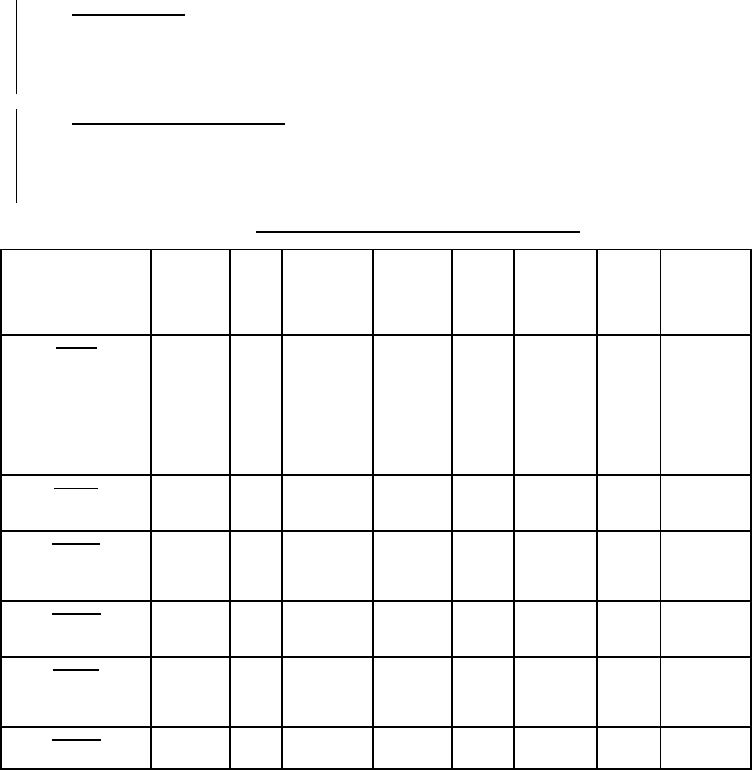

TABLE XII. Sequence for examinations, measurements, and tests.

Resistance

Dielectric

Independent

measured

withstanding

Setting

Insulation

Examination

Total

Peak

linearity

between

Torque

voltage (at

stability

resistance

or test

resistance

noise

tolerance

terminals

atmospheric

1,3

pressure)

Group I

Visual and mechanical

A

Examination

Actual effective-electrical

A

A

A

A

Travel

Absolute minimum

Atmospheric

resistance

and

Barometric

End resistance

Continuity Thermal

B, A

B, A

A

shock

Group II

Resistance-temperature

characteristic

Moisture resistance

B, A

A

A

Group III

Acceleration

B, A

B, A

A

Shock, specified pulse

B, A

B, A

Vibration, high frequency

B, A

A

A

B, A

A

Salt spray (corrosion)

Group IV

Resistance to soldering

B, A

heat

Life

B, A

A

A

A

A

B, D, A

B, A

A

Group V

Low temperature

B, A

B, A

B, A

operation

High temperature

A

A

A

A

B, A

A

exposure

Group VI

Rotational life

B, A

A

A

Terminal strength

B = Before test, D = During test, A = After test

24

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business