MIL-PRF-39035E

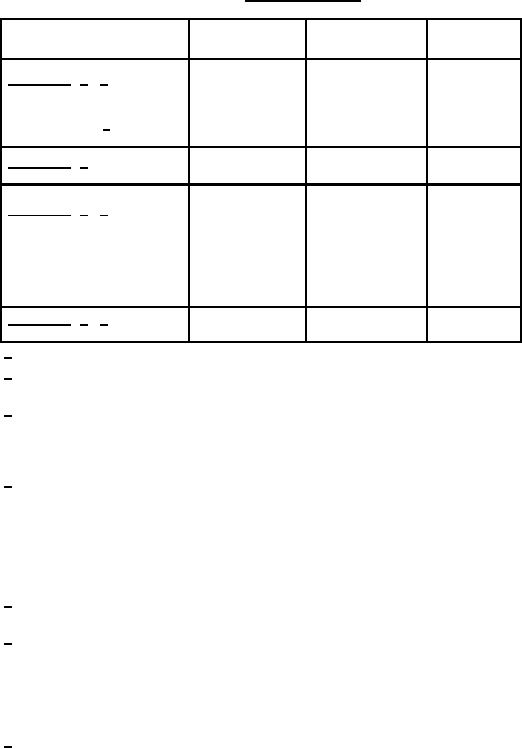

TABLE VII. Group A inspection.

Requirement

Test method

Sampling

Inspection

paragraph

paragraph

procedure

Subgroup 1 1/ 2/

Conditioning

100 percent

Contact resistance variation

inspection

Total resistance 3/

Immersion

Subgroup 2 4/

See 4.6.3.2.3

Visual examination

Subgroup 3 5/ 6/

End resistance

Actual effective electrical travel

See 4.6.3.2.4

Dielectric withstanding voltage

Insulation resistance

Torque

Thermal shock

Subgroup 4 5/ 7/

See 4.6.3.2.5

Solderability

1/

100 percent solder dip may be performed prior to immersion (see appendix A).

2/

At the manufacturer's option, the determination of resistance change may be by

any method which is within the accuracy requirements of this specification.

3/

Resistors shall meet this specified initial resistance tolerance. The resistance

measurement made upon completion of the power conditioning test may be used if

a measurement was made which can, without conversion, be directly related to

nominal resistance value and tolerance.

4/

The manufacturer may request the deletion of the subgroup 2 visual examination

test, provided an in-line or process control system for assessing and assuring the

applicable requirements of the visual examination test can be validated and

approved by the qualifying activity. Deletion of the test does not relieve the

manufacturer from meeting this test requirement in case of dispute. If the design,

material, construction, or processing of the part is changed, or if there are any

quality problems, the qualifying activity may require resumption of the test.

5/

At the option of the manufacturer, subgroup 2, subgroup 3, and subgroup 4 may

be performed concurrently with a separate set of samples.

6/

If the manufacturer can demonstrate that this test has been performed for 6

months with zero failures, the frequency of this test, with the approval of the

qualifying activity, can be performed on an annual basis. If the design, material,

construction, or processing of the part is changed, or if there are any quality

problems or failures, the qualifying activity may require resumption of the original

test frequency.

7/

The manufacturer may request the deletion of the subgroup 4 solderability test,

provided an in-line or process control system for assessing and assuring the

solderability of leads can be validated and approved by the qualifying activity.

Deletion of the test does not relieve the manufacturer from meeting this test

requirement in case of dispute. If the design, material, construction, or processing

of the part is changed or if there are any quality problems, the qualifying activity

may require resumption of the test.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business