MIL-PRF-39005G

4.6.3 Group A inspection.

4.6.3.1 Non-ER resistors. The manufacturer shall establish and maintain an inspection system to

verify that resistors meet dc resistance, visual/mechanical examination, and solderability requirements.

In-line or process controls may be part of such a system. The inspection system shall also include criteria

for lot rejection and corrective actions. The inspection system shall be verified under the overall

MIL-STD-790 QPL system. NOTE: Since the non-ER (C level) is the ER design without the mandatory

conformance inspection and FRL assessment, this product is still expected to meet the environmental

qualification type requirements of the ER part, such as moisture resistance, shock, and vibration..

4.6.3.2 ER resistors. Group A inspection shall consist of the examinations and tests specified in

table X, and shall be made on the same set of sample units, in the order shown.

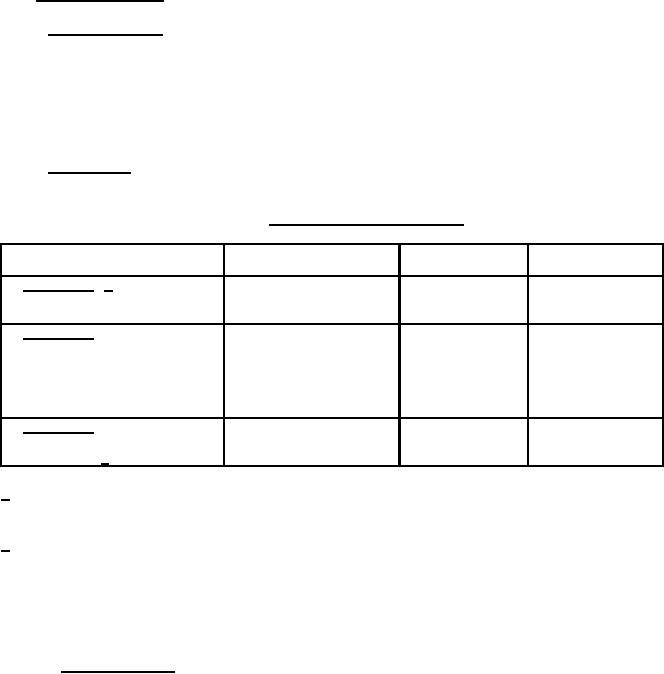

TABLE X. Group A inspection (ER only).

Inspection

Requirement

Test method

Number of

paragraph

paragraph

samples

Subgroup 1 1/

Conditioning

100

DC resistance

percent

Subgroup 2

Visual and mechanical inspection

Body

Lead dimension

See 4.6.3.2.3

Marking

Workmanship

Subgroup 3

Solderability (applicable to "L"

See 4.6.3.2.4

terminal only) 2/

1/ At the manufacturer s option, the determination of resistance change may be by any method which

is within the accuracy requirements of this specification.

2/ The manufacturer may request the deletion of the subgroup 3 solderability test, provided an inline

or process control system for assessing and assuring the solderability of leads can be validated

and approved by the qualifying activity. Deletion of the test does not relieve the manufacturer from

meeting this test requirement in case of dispute. If the design, material, construction, or

processing of the part is changed or if there are any quality problems, the qualifying activity may

require resumption of the test (see appendix A).

4.6.3.2.1 Subgroup 1 tests. Subgroup I tests shall be performed on 100 percent of the product

supplied under this specification. Resistors that are out of resistance tolerance, or which experience a

change in resistance greater than that permitted for the test of this group, shall be removed from the lot.

Lots having more than 5 percent total rejects, or one resistor, whichever is greater, due to exceeding the

specified resistance change limit, shall not be furnished on the contract or order.

16

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business